Antipyretics for children are prescribed by a pediatrician. But there are emergency situations for fever in which the child needs to be given medicine immediately. Then the parents take responsibility and use antipyretic drugs. What is allowed to be given to infants? How can you bring down the temperature in older children? What are the safest medicines?

Even the very word "gold" magically affects a person, not to mention his form. Let the dreams of gold-bearing rivers and mines remain dreams. However, for those who still want to feel like a gold miner, a very real way can be offered - gold mining at home. Of course, we are not talking about kilograms, but you can get enough metal to use it for practical purposes.

Properties of gold

Gold is a precious metal that is widely used in jewelry. However, in addition to the jewelry value, it should be noted that its unique electrical conductivity determines its use in electronics, where it is necessary to provide low resistance in very important parts with minimal dimensions. It is these details that become the main raw materials for home gold mining.

When organizing the extraction and processing of gold, one should take into account its main properties:

- Large specific gravity. This characteristic is used in the implementation of technology such as washing, when a large weight causes gold particles to settle.

- High ductility, facilitating the forging of metal when making jewelry from it. Very fine threads can be made from gold.

- Inertia. Gold does not react chemically with most of the known acids, alkalis and solvents. Only "aqua regia" and some solvents are capable of affecting it. This property is very important for the organization of the mining process.

- A lower melting point compared to other metals and minerals, which allows you to smelt gold from products and make jewelry from the melt.

Attention. Being in a molten state, gold quickly evaporates, which must be taken into account when melting it.

Where is gold contained

The home craftsman needs to tune in to the laborious and painstaking process, because available raw materials have a scanty gold content, moreover, it is difficult to recover. Precious metal can be obtained from the following materials:

- Parts of radio equipment and electronic devices - microcircuits, transistors, diodes, capacitors, resistors, switches, motherboards, connectors, processors. A sufficient amount of gold for extraction is contained in a relay of type RES, RPS, RPV, RKG; lamps of old radios and televisions. The radio tubes of the GMI series stand out. Gold-containing parts can be found in televisions, radios, computers, tape recorders, VCRs, mobile phones, refrigerators, and other household appliances. The presence of such parts, as a rule, was indicated in the equipment passport. Modern technologies make it possible to do without the use of precious metals, and therefore they should be looked for in the details of old devices and devices. It should be noted that Soviet-made products were distinguished by a large number of valuable parts.

- Bijouterie... Gold can be extracted from spoiled, damaged, worn out earrings, rings, pendants, pendants, brooches and other jewelry that are gilded or interspersed with valuable elements.

- Watch... Of interest are products with dusting on the case or hands, bracelets.

- Cutlery and souvenirs ... These can be forks, spoons, dishes, figurines, gold-plated decorations.

Home mining process step by step

Home gold mining can be organized in several ways. They are based on the following principles:

- Dissolving the base ... Products with surface gilding (watches, dishes) to obtain precious metals, it is enough to expose them to a powerful solvent. This technique is based on the unique inertness of gold, which is not affected even by concentrated acid. To implement the method, it is enough to place the sprayed product in a glass container and fill it with concentrated nitric acid. All metal parts will dissolve in 3-4 days, and gold will precipitate.

- Etching ... This principle is based on the complete dissolution of details. In order to dissolve gold, you will need a "hellish mixture" in the form of a combination of hydrochloric and nitric acids - "aqua regia". In such a liquid, gold only dissolves, and all other ingredients do not just dissolve, but chemically react with an acid, forming the corresponding compounds. Under these conditions, the introduction of the required reagents makes it possible to precipitate gold from solution. As they can be used hydroquinone, hydrazine, hydrogen peroxide, sodium sulfite, ferrous sulfate. Etching technology is most suitable for extracting gold from small parts of electronic devices.

- Electrolysis. High purity gold can be obtained by electrolysis. A gold-containing radio component serves as an anode, and 2 lead or iron plates are installed as a cathode, connected from above by a conductor. The electrolyte is hydrochloric acid. When a direct electric current is passed (with a density of 0.6-0.7 A / sq. Dm3 of the anode area), gold gradually passes to the cathode plates and settles on their surface.

Gold etching techniques

When implementing these methods for obtaining gold from various parts, a certain procedure must be followed. The first mining option provides for the following works:

- Accumulation of a sufficient amount of raw materials. Removing all items that have no value. Only gold-plated elements with a minimum content of other materials are prepared for processing.

- Placing raw materials in a glass container and filling with concentrated nitric acid.

- After 3-4 days (provided that the base is completely dissolved), the solution is filtered through gauze layers.

- The resulting precipitate is placed in a glass container and filled with ethyl alcohol or vodka. Exposure is 22-25 hours.

- The brown precipitate is washed and filtered, and then sent to melting. To obtain a purer metal, it is recommended to add soda to the melt.

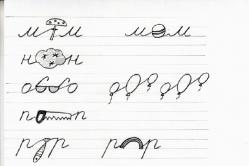

Most often, gold from radio components is mined by etching. This technology is implemented in the following sequence:

- Accumulation of sufficient raw materials for processing.

- Preparation of "royal vodka". In a glass container, hydrochloric (3 parts) and nitric (1 part) acid are mixed with utmost care.

- Raw materials are cleaned of dirt and loaded into "aqua regia".

- The liquid is heated to accelerate dissolution. The process is complete when the parts are completely dissolved and the solution turns bright green.

- Gold deposition. For these purposes, you can use a solution of hydroquinone, prepared by adding 50 g to 1 liter of water. This composition is carefully poured into a vessel with "aqua regia", adhering to a concentration of 10 ml of hydroquinone per 1 liter of solvent. Further, the container is left for 3.5-4 hours.

- The solution is carefully filtered, and then the gold deposited on the bottom of the container is evaporated and dried. The precipitate looks like thin yellow foil patches.

How to store etched finished metal

Home gold mining is characterized by scanty portions of the precious metal, and therefore it is necessary to minimize its losses. So, at the final stage of gold evaporation, it is recommended to add borax and soda to the resulting sediment, which will reduce waste and simplify further processing. It is better to immediately pour the resulting metal into specially prepared forms (crucibles).

Small burners or muffle furnaces are used to melt gold. The molds are made of cast iron or alloy steel and have a collapsible design. Most often, gold is stored in the form of small bars. Depending on the amount of final product obtained, it is sometimes shaped into rods or wires.

Features of working with reagents

Home gold mining will have to deal with highly corrosive and harmful chemicals. It must be remembered that acid fumes (especially when heated) are extremely dangerous for the human body.

In the process of work, nitric oxide is released, which can affect the respiratory system, up to death. Frequent and prolonged inhalation of harmful substances can cause chronic diseases. Concentrated acids can lead to severe chemical burns, both of the skin and mucous membranes.

Important. When working at home, you must strictly follow the precautions. Good ventilation of the room must be ensured at all stages. You can only work with rubber gloves, goggles, a respirator and a protective apron.

Using the received gold

Home-obtained gold can be used in many ways. At the same time, one should not forget that obtaining a permanent income in this way requires obtaining an appropriate license. In general, the following options stand out:

- Selling gold bullion or handing it over for sale. To give the desired appearance, they are polished using a toothpaste applied to the rough metal surface with felt.

- Preparation of jewelry solder for repairing gold jewelry. Such solder is made by mixing the obtained gold with various additives. For example, the following solder recipe is used to repair products with 585 fineness: gold - 585 parts by weight (wp), copper - 185 wp, silver - 116 wp, cadmium - 112 wp. For ease of use, the solder is prepared in the form of a paste - tinol.

Jewelry making

At home, you can make various simple jewelry - earrings, pendants, rings, rings, chains. The most common method is casting into special molds. The resulting precious metal is melted in small containers with a spout. Heating to the required temperature is provided by a muffle furnace. Further, the melt is directed in a thin stream through the hole into the mold. If necessary, the metal is carefully forged. Making complex products requires a set of special tools from the jeweler.

Mining gold at home, with your own hands, is, although laborious, but quite a doable process. The precious metal can be found in old radio equipment and various electronic devices. Extraction requires chemical reagents, which must be handled with utmost care. Gold lies idle nearby, and it can be mined without looking for a gold mine.

Even those who have never been involved in such a craft are interested in this question. It should be noted that there is not so much precious metal on our planet, the amount of its production does not exceed 1 thousand tons per year. The very same gold mining began a little over 6.5 thousand years ago.

The first gold items were found in Bulgaria and dated back to 4500 BC. NS. Such a short history of mining allowed mankind to replenish the reserves of this metal by only 168.9 thousand tons.

Mined gold bars

How does gold appear?

Interest in gold has arisen relatively recently, but despite this, the metal itself appeared on our planet at the time of its formation. Many scientists believe that gold arises from the explosion of a neutron star, the particles of which start the formation of planets and solar systems, in some way consisting, including of gold.

Most of the metal is concentrated in the molten core of the Earth, and only a small amount is close enough to the surface to become available for mining. In addition, some of the metal reaches the surface with volcanic lava flows. Also, the metal can be found in places where postmagmatic and hydrothermal processes take place.

Speaking about how it appears and how to get gold on Earth, one should not forget about space. Every year, many meteorites fall on the planet's surface, some of them are made of gold. Finding such a meteorite is rare, but still possible.

Gold was and remains one of the most valuable metals. In the conditions of its limited quantity, the demand for it has remained unchanged for many centuries.

History of the development of gold-bearing veins

The first large gold-bearing veins were found in Africa, Asia and America. Legends about the mysterious and inaccessible Eldorado - a land full of gold and precious stones - still excite the hearts of adventure lovers to this day. Modern gold mining is carried out on all continents, gold-bearing veins have been found in the countries of South America, Australia and China.

Amateurs-gold diggers use various mini-equipment

Amateurs-gold diggers use various mini-equipment One of the largest gold mining states is the Russian Federation. The country is in fourth place in the extraction of precious metal.

The first gold-bearing veins on the territory of Russia, and the whole world, were mined by hand, which had an impact on the quality, quantity and speed of gold mining. For the first time, the industrial mining method was applied in 1745. The first gold mine was opened by a peasant Erofei Markov, later it was known as Berezovsky.

Today, about 16 companies are in charge of metal mining in the Russian Federation, each of which replenishes the state gold-bearing reserve by several tens of kilograms per year. Gold mining is carried out in the Irkutsk Territory, Magadan, Chukotka, Amur Region, Krasnoyarsk and Khabarovsk Territories.

Before the invention of the industrial mining method, the essence of which is described below, gold was mined exclusively by hand. This process was costly, time consuming and even dangerous. Actually, it was made dangerous by the presence of other gold miners, wild animals, weather conditions and the vicissitudes of fate, which even the most fortunate profit seekers faced more than once.

Production methods

Modern technology has improved many areas of human activity. The extraction of precious metals is no exception in this regard. The introduction of new scientific developments allows them to be mined in places whose potential has dried up several decades ago. The profitability of a gold deposit is determined by the amount of gold.

A deposit in which 1 ton of sand accounts for 3 grams of gold is considered to be a payback and even very profitable one. Deposits in which up to 10 grams of metal can be obtained from 1 ton are listed as rich, but there are very few such places on the planet. Most of the rich deposits were developed in the first half of the last century.

There are several ways to obtain precious metal from sand and gold ore:

1) Sifting and washing the sand by hand. Practically not used lately. The method was widely used during the gold rush years in the USA and Australia. The bottom line is to use large sieves, lattice-bottom buckets and bags. Before gold was mined on an industrial scale, gold-bearing veins were located in large quantities in the channels of large, but relatively small rivers. All that was required of the miners was patience and dexterity.

People entered the river up to their waist, and sometimes up to their necks, scooped up river sand and poured it onto a special sieve. With the help of a sieve, which was kept on the surface of the water all the time, it was possible to get rid of the sand and water, leaving only large stones, among which there were also golden grains of sand. If gold-bearing veins were found near the coast, the task of gold miners was simplified.

Manual gold flushing

Manual gold flushing This mining method required skill and maximum concentration. In northern latitudes, it was also seasonal. The resulting metal was sold in its pure form. It was accepted as payment for goods and services rendered in any part of the world. Unfortunately, it was not possible to extract a large amount of metal in this way.

Small gold-bearing grains of sand could be found already at a depth of 10-12 centimeters, but in order to obtain richer mining, gold prospectors had to dig up river soil to a depth of half a meter or more. The main sign of the presence of metal in the river, or stream, was the presence of quartz pebbles. Sand washing has long been the only way to obtain metal.

2) Extraction of metal from gold-bearing ore. Was conducted manually. The main tools were a shovel, a pickaxe, a hammer for crushing ore. A dangerous method of mining, requiring the ability to climb mountains, dig deep trenches and even mines. Metal mining in this way has been carried out for a long time on the territory of Russia.

3) Industrial mining. Thanks to the discovery of certain chemical compounds, the mining process has accelerated significantly. Large and small equipment is used in mining, the process is well-oiled and automated. Modern industrial mining methods are:

- Almagallization. In the middle of the last century, such a method of mining metal as almagalization was popular. The essence of the method was to use the ability of mercury to attract gold, enveloping it. To detect grains of metal, gold-bearing ore was poured into barrels, the bottom of which was covered with mercury. All the gold stuck to the mercury, and the devastated ore was disposed of. Subsequently, the barrel was heated, and the metal exfoliated from the mercury. This method was ideal in terms of cheapness and ease of metal production. For a long time, it was the main mining method. At present, almagalization has been almost completely abandoned, which is associated with the danger that toxic mercury poses to others. In addition, mercury still does not completely give up gold, some particles remain, which is simply not cost-effective given the high value of the metal. Currently, gold is mined using slightly different methods.

- Leaching of metal with sodium cyanide. Allows you to get metal even from already processed gold ore. Gold-bearing particles are initially transformed into water-soluble cyanide compounds, after which, with the help of special reagents, a solid form is returned to them.

- Flotation. Some gold-bearing rocks do not get wet, but are enveloped in liquid particles and, like air bubbles, float on the surface. To obtain gold from such a rock, it is crushed, filled with water or pine oil, and then mixed. The gold particles contained in the ore float to the surface, after which they are cleaned. On an industrial scale, oil is replaced with air - it is passed through a mixture of ore, water and some chemical elements.

4) Extraction at home. Gold literally surrounds people, however, many never notice this and therefore do not suspect that it is quite real. A small amount of gold is contained in old Soviet-made wristwatches, radio components and even ordinary seawater. To get gold at home, you need to collect a large number of watches (at least several hundred), put them in a glass bowl and fill with nitric acid. After some time, the acid will dissolve all metals except gold.

The resulting sediment is filtered through several layers of gauze, after which the rest of the gold is poured with vodka and left for a day or more. Over time, the gold is washed again and re-melted. During the smelting process, a little soda is added to the gold. The weight and size of the resulting ingot will be slightly different from the original. The mining process is similar.

So, the past millennia have changed a lot in the methods and. One thing has remained unchanged - the attractive value of this metal in the eyes of people.

Gold is the precious metal that can enrich a person. Therefore, the question of what gold can be obtained from worries many people. It is especially interesting that the methods can be used even at home.

These techniques are not concerned with finding treasure near your home or digging into the soil. Gold is present in small quantities in parts and mechanisms. The main task of the seeker is to collect small things and extract precious metal from them. Therefore, before extraction, care must be taken to collect scrap or items with sufficient gold content. If there are few items, there is a risk that the action will not pay off. Most techniques for extracting gold from objects require chemicals.

Gold from radio components, microcircuits and mobile phones

Precious metal cleaning

Mining gold at home requires choosing the location of reagents and gold-containing items. To do this, it is worth purchasing such equipment:

- Scales with high measurement accuracy. You can buy jewelry.

- Several buckets and bowls made of plastic.

- Electric stove (for heating and melting metals).

- Heat-resistant saucepan or dish made of special glass.

- Brushes.

- Concentrated nitric acid.

- Blade.

- Water and cheesecloth or filter cloth.

- Rubber gloves and a respirator for protection.

- Alcohol or vodka.

- Hydrazyl hydrochloric acid.

All reagents are available from specialized markets or stores. Sometimes finding them in large volumes is the most difficult task of the entire process. After all the substances are ready, jewelry, radio parts or scrap gold can be dipped into a basin with nitric acid. The base material will dissolve and the gold will remain unchanged. The precious metal that remains in the basin should be filtered together with the solution through cheesecloth and filter paper.

The next step will be to flush the formed precious metal with water. And then it should be dipped in a solution of alcohol or vodka. After holding for five minutes, hydrochloric acid hydrazyl is added to the solution to precipitate the metal. The amount of reagents does not matter. The main thing is that the solution completely covers the gold. In this form, the container should be left overnight in a warm place.

After a night, a sediment similar to greasy clay, which has a brown tint, will appear in the container. Waste reagents can be rinsed with distilled water. The sediment is then passed through a filter or gauze and dried. But this is not the final stage, the production of gold continues.

Next, you need to put the resulting substance in a crucible for precious metals and heat it on a gas burner. During the heating process, the gold particles will merge into one alloy or ingot. And such a substance will contain a small amount of impurities, to remove which you need to use borax or soda.

It is soda that is able to prevent the loss of gold when heated. The resulting ingot must be poured with cold water with the addition of citric acid, so that the substance acquires a shine.

Other ways to get gold yourself

There are also techniques that allow you to extract gold from water or sand. Sea water is especially popular for the amount of gold. After all, the world's reserves, according to scientists, are at the bottom of the ocean. It has been proven that the precious metal is contained in these substances, only in very small quantities. Therefore, the isolation process is more complicated than from previous materials. It rarely pays off and is able to satisfy only those gold miners who work for themselves and take metal mining as a hobby.

To do this, you can use sea water by collecting a few bottles on the beach. Then the resulting water must be mixed with milk of lime. The solution must be placed in the sea several times, and then the precious metal must be extracted from the sediment.

You can also get gold from radio components. Just find out which items are suitable, you need magnetic or non-magnetic parts. Or you can extract gold from the processors of old computers, SIM cards from mobile phones.

Among the methods of obtaining gold there is also the option of independent mining of precious metals near mines or placers. Prospectors always work on their territory. Before making a minidrag or other mining equipment, obtain a work license from the head of the enterprise.

There are advantages to this type of business. After information on how to mine gold at home, you need to understand the advantages of the technique. The process itself is not too complicated, does not require preparation and costs. And jewelry making or just mining can be carried out at home, outside of special laboratories. The following factors can be distinguished as advantages:

- Free working day, the schedule does not require constant presence. Gold mining is easy to combine with the main job.

- The process pays off, there is an opportunity to allocate purer gold and sell at a higher price.

- Chemical reagents are required, but not in large quantities, and it is also not necessary to have education, tools.

The disadvantages of such a process are its insecurity. In particular, work with acids and alkalis requires caution. It is necessary to protect not only the skin from the ingress of reagents, but also the mucous membranes. Therefore, it is better to work in a respirator, glasses. Initially, the process can be slowed down in order to get a handle on the extraction of precious metals and not get burns or more serious injuries.

If you do not want to be engaged in self-mining of gold, but you have a large number of gold-containing items, then you can take them to the purchase of people who extract the precious metal. Of course, the amount for the items will be calculated based on the accessories, and not the gold that will be obtained from them. This business option is less profitable, but safe.

Scientists, in turn, tried to extract gold from less valuable metals. So, experiments were carried out to extract substances from such metals:

- lead;

- mercury;

- silver.

All these studies were carefully analyzed and turned out to be nothing more than a mistake of scientists. Most metals initially contained gold impurities, just in the process of research, scientists isolated particles already embedded in the structure. Therefore, now the dream of alchemists still remains a dream, but people do not give up and continue to work towards obtaining an artificial precious metal.

Gold mining began in ancient times. Throughout the history of mankind, approximately 168.9 thousand tons of the noble metal were mined, almost 50% of which goes to various jewelry. If all the mined gold were collected in one place, then a cube with a height of a 5-storey building with an edge of 20 meters would be formed.

"Golden story"

Gold is a metal that humanity was introduced to at least 6500 years ago. The most ancient treasure is considered to be found in the Varna necropolis, which is located in Bulgaria, and the items are dated to 4600 BC.

Gold has played an important role throughout human history and is still considered a safe investment. Currencies have come and gone, but it has remained a universal and stable benchmark for thousands of years.

It has always been prestigious to own this metal. The amount of gold was used to assess not only welfare, but also the position in society depended on it. This is the case to this day.

It was gold that was often the cause of wars and crimes, but at the same time it played a huge role in the progress of mankind in general. On its basis, a monetary system began to take shape, cultural values and architectural masterpieces were created, which are priceless and still amaze everyone. Thanks to the desire to produce this metal, scientists have obtained many chemical elements, and gold rushes helped to discover and develop new lands.

How gold is mined in Russia

In the upper crust of the earth's stratum, gold is contained in small quantities, but there are quite a few such deposits and areas. Russia is in 4th place in the ranking for its production and has 7% of the world share.

Gold mining began in an industrial way in 1745. The first mine was opened by the peasant Erofei Markov, who announced its location. Subsequently, they began to call him Berezovsky.

Today, there are 16 companies in Russia that mine this precious metal. The leader is Polyus Gold, which has 1/5 of the entire mining market share. Diligent artels mainly mine metal in the Magadan, Irkutsk and Amur regions, Chukotka, Krasnoyarsk and Khabarovsk regions.

Gold mining is a complex, time consuming and costly process. Reduce such costs by closing low-profit and unprofitable mines. Reducing the volume and introducing new technologies that save capital are quite effective measures.

Gold mining process

As the centuries passed, the process of extracting this metal was constantly changing. Initially, manual gold mining was popular. Prospectors obtained golden dust thanks to simple primitive devices. River sand was collected in a tray, and then shaken in a stream of water, the sand was washed away, and grains of metal remained at the bottom, since they are heavier. This method is often used today.

However, this is not the only mining process. For example, it used to be common to find gold nuggets along rivers. They were thrown out on land when the gold-bearing veins were naturally eroded. However, by the twentieth century there were no rich placers left, and they learned to extract gold from ore.

Nowadays, manual gold mining is rarely practiced, the process is completely mechanized, but at the same time it is very complex. A deposit is considered to be profitable, in which 3 g of gold are accounted for per ton. When it contains 10 g, it is considered rich.

A few years ago, a method such as amalgamation was often used, which is based on the special property of mercury to envelop gold. Mercury was placed at the bottom of the barrel, then the gold-bearing rock was shaken in it. As a result, even the smallest particles of gold just stick to it. After that, the mercury was separated from the waste rock, and the gold flaked off with strong heating. However, this method also has disadvantages, since mercury itself is very toxic. At the same time, it does not give away gold completely, since very tiny particles of precious metal are poorly wetted.

The second method is more modern - gold is leached with sodium cyanide, which is able to convert even the smallest particles into water-soluble cyanide compounds. And then gold is extracted from them with the help of reagents. In this way, it is possible to obtain precious metal even from the already existing ones, which makes them profitable again.

Getting gold at home

Manual gold mining is also possible at home. In order to get it, you do not need to go to the mines and shake the trays for hours. There are calmer and more civilized methods. There are a lot of items around that contain gold. For example, old Soviet watches in their yellow cases contained the purest precious metal without impurities.

In order to get it from there, you just need to buy such a watch in very large quantities. Then you will need a plastic bucket and basin, an electric stove, razor blades, a heat-resistant glass pan, a brush and cotton cloth for filtering, rubber gloves and a spray bottle. Of the chemicals, nitric and hydrochloric acids are needed.

Recycling starts when you already have 300 hulls on hand. The process will take only 4 hours, and you will use up 4 liters of acid. From this number of cases, you can get 75 grams of pure gold.

Who would have thought, but everyone, even children, carry gold in their pockets and bags every day. It's simple - each SIM card for a mobile phone contains a certain amount of precious metal. It can be extracted from there as well. This is done in two ways: electrolysis or etching. For the latter, the chemical reagent "aqua regia" is required.

Etching is considered the simplest method, in which gold is obtained due to the chemical inertness of the precious metal, namely, its ability to react with other elements. For etching, an oxidizing agent "aqua regia" is required, which is made from concentrated acids: hydrochloric and nitric. The liquid has an orange-yellow color.

Gold from water

Gold mining is also possible from water. It is also contained in it, and in any: sewer, sea, water supply, but in very small quantities. For example, in the sea, it exists in the proportion of 4 mg per ton. Despite this, it is still possible to extract it with the help of quicklime, which will require only a ton for 4.5 thousand tons of water.

In order to get gold from sea water, you need to mix it with milk of lime. After a while, the liquid must be released back into the sea, and the precious metal must be extracted from the sediment. Kirovsk engineers propose another waste-free method in which lime is replaced by ash from thermal power plants. This method is considered the least expensive of all known.

Golden bacteria

In Canada, scientists have generally found bacteria that are capable of separating gold from various solutions. Amazing, isn't it? For example, the bacterium Delftia acidovorans has a substance that separates the precious metal from the solution. And the reason is simple - it just defends itself, protecting itself from gold ions, which are toxic to it. The second bacterium Cupriavidus metallidurans, on the contrary, accumulates it inside itself.

Both were found in 2006 in gold mines. Studies in Canadians have shown that the bacteria that accumulate gold avoid poisoning due to their genetic nature.

Draghi

Gold is also mined with dredges. They are called floating mining machines that have dredging, ore dressing or other equipment that provide comprehensive mechanization of the mining process. They enrich minerals and remove

The purpose of the dredges is to develop watered mineral deposits and extract valuable components (gold, platinum, tin, etc.). They are used mainly in alluvial, deluvial, deep and coastal marine sedimentary and placer deposits. The only exceptions are bouldery, hard rocks and viscous clays.

Types of dredges

Draghi are divided into two classes.

- Offshore, with the help of which deposits of the coastal zone and deep mines in lakes and oceans are developed. They are mounted on keeled towed or self-propelled vessels, which ensure operation during storms.

- Continental, which are used for the development of deposits on the continents. Mounted on a flat-bottomed boat.

Dredges are classified according to:

- the type of energy used by the drive mechanisms;

- deep excavation of rocks in the section below the water level;

- the kind of apparatus (many scoops with an intermittent chain, with a solid chain, a rotary complex, a dragline bucket, a grab bucket);

- scoop capacity (large, medium and small);

- method of maneuvering (rope-anchor and rope-pile).

On the territory of the Russian Federation, dredges are now used for gold mining, mainly in the Far Eastern Federal District. However, mining using this method can negatively affect the ecosystem, destroy river landscapes, and severely pollute the territory that is located downstream.

Therefore, this method can only be used with careful adherence to development projects. Their implementation will require reclamation of lands that have been disturbed by mining operations, as well as restoration of forests, soil and vegetation of river valleys.

How to make a dredge for gold mining yourself

Many gold miners would like to have their own dredge, while saving a lot on costs, as the prices of this equipment are very high. In this case, the easiest way is to do it yourself. Despite the fact that the most inexpensive materials will be purchased, a certain amount of money will still be required to create a dredge.

Initially, you need to draw up lists and assembly diagrams, for this you can take as an example the most famous dredges for gold mining at the moment. Basically, the first stage is studying, the more you know about them, the better and better you will make your own.

Some important parts can be found in an ordinary landfill, and you can buy them for a song, for example, the engine for the apparatus. Next, you need to decide on the size of the dredge, the larger it is, the more soil can be processed, but its weight and cost will also be higher than that of a small assembled product.

You need to build it with a hose diameter of up to 12 cm so that you can handle the dredge yourself. The most optimal size is 10 cm. If you need compressed air, you need to purchase an air compressor, diving equipment and an air intake tank. However, this is not the first need, it can be done only later.

In order to build the coveted apparatus, you will need: an engine with a pump, a variety of tools (hacksaw, hammer, wrenches, screwdrivers). It will not hurt to purchase a welding machine. You can buy used parts, but some, especially important and problematic or difficult to replace, it is better to buy new ones in the store.

Some dredge parts are often impossible to make with your own hands, so you still have to purchase them: an engine, a water pump, an air compressor, a hose, an ore washing chute. It is the latter that is the most important detail, without it the gold is simply not captured, respectively, the entire constructed apparatus loses its meaning.

The dredge bell should be installed in the head of the sluice so that it directs the flows of water and soil into it. The suction valve draws water into the pump (this is also one of the important details). If sand is sucked in, the pump can quickly break down, so you cannot dredge without a valve.

A hydraulic elevator is placed at the end of the hose, while water is supplied to the beginning and a vacuum is created. It is best to use a suction nozzle here. It is difficult to operate the elevator on large dredges, therefore it is mainly used on small machines, if the work takes place in shallow water.

The buoyancy of the apparatus is a separate stage in the creation of a dredge. It can be provided in several ways. Originally used tires from trucks, they weigh a little and are cheap. The only obstacle is that getting them is not as easy as it might seem. However, this would be the best option.

Now many manufacturers of dredges use them. They are quite reliable, but also heavy. However, there are many options here as well. Some homemade dredges have different plastic pontoons. One of the interesting ways is when they use plastic containers or barrels with a capacity of up to 40 liters. You can buy them quite inexpensively. If you are not sorry to spend a large amount, but buy ready-made, then it is easier to purchase from the manufacturer.

Another important part that affects buoyancy is the frame. It is on it that the motor and the ore washing chute are attached. If you do it yourself, then you can take simple pieces of aluminum, which are easy to find in any landfill. It will be inexpensive, almost no effort is required. If the frame turns out to be flat, then the tires from the truck are simply attached to it.

You can check the work of the dredge after its complete assembly. To do this, take two dozen small pieces of lead, which are aligned and painted in a bright color. Soil is collected in the reservoir, and they are placed there. It is on it that you can try the dredge. See how many pieces of lead came back after flushing the rock. During normal operation of the dredge, losses are possible only up to 2 pieces. If there is not enough lead, then the entire assembly should be checked again according to the scheme, and if necessary, additional improvements should be made.

Gold mining plans in the future

Gold deposits are becoming less and less, they are now being discovered mainly in South Africa, others are significantly depleted, and it is simply unprofitable to develop deposits with a low and medium content of precious metals.

According to experts' forecasts, the reserves of minerals that contain gold can be developed for another 50 years. Then they will run out. Simply because mankind has been mining gold very intensively in recent decades. And it becomes less and less in nature. Now we have to find new opportunities for the extraction of this metal in the coming years. Gold leaching technology is considered the most promising method.

In recent years, there has been a lot of talk about the development of the ocean as another way of mining gold. There are a lot of sea deposits and deposits, but the bottom has not yet been fully explored. It is possible that it is in the ocean that most of the deposits of the precious metal are hidden. Our descendants will have to find out.

You will need

- - buckets;

- - fine mesh filter;

- - gravel;

- - two bottles of electrolyte;

- - half a bottle of Whiteness;

- - chlorine tin for testing;

- - inkstone;

- - nitric acid for gold purification;

- - writing paper for the filter;

- - hose;

- - syringe;

- - gas-burner.

Instructions

So, gold from the earth? Pick up 6-9 buckets of gravel (about 300 kg). You can take any land. Atomic gold is everywhere. But it is better to collect gravel not far from some gold-bearing deposit.

Pour water into the bucket. Take a thick cloth and start filtering the gravel through it in small portions. The end result should be a very saturated earthen solution. On top of it, foam will be noticeable - dissolved salts, which need to be disposed of.

Add about a glass of electrolyte to the solution. This step is optional. However, with the use of an electrolyte, you can end up with more gold. The fact is that the latter is contained in the soil in the form of very small scales. Due to the adhesion of dirt particles to them, they very slowly settle to the bottom (within a few days). With an electrolyte, the answer to the question of how to make gold will be easier, since the deposition process will go much faster.

Leave the earthen solution with electrolyte to settle for a day. After a day, remove excess liquid from the bucket using a hose. Pour a bottle of electrolyte and half a bottle of Whiteness into it.

If you want to know how to make gold through such an experiment and not get hurt, follow the safety precautions. Add electrolyte and whiteness to a bucket somewhere in the garden or even in an open field. The reaction of these two substances gives a very strong smell, and the vapors released during it are harmful to health. Wear a respirator to avoid poisoning. Close the bucket itself with a lid.

Once the reaction is over, filter the gold solution through a very fine filter. You should end up with a perfectly clear orange liquid. Gold can be distinguished from it.

Check for gold in the solution. Drop some tin chloride into it. Darkening of the liquid while stirring with drops indicates the presence of gold. Evaporate the resulting orange solution to approximately 1 liter. Filter it again.

So, we got a clean, concentrated solution. So how do you make gold out of it? In order to obtain this precious metal, pour iron sulfate into the solution until it darkens strongly. Wait for a precipitate to settle. Collect excess fluid with a syringe. Filter the sediment through writing paper. Alloy the resulting gold mass together with the filter using a burner. Toss the resulting piece of gold into nitric acid for cleaning.