Antipyretics for children are prescribed by a pediatrician. But there are emergency situations for fever when the child needs to be given medicine immediately. Then the parents take responsibility and use antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? What medicines are the safest?

Today, the Russian shoe market is highly dependent on foreign manufacturers. The rapid rise in prices for imported shoes attracts an increasing number of buyers to the domestic manufacturer. Therefore, entrepreneurs can think about opening their own shoe factory.

Shoe production technology

All technology is divided into stages. The first stage of shoe tailoring begins with a cutting shop, the components of the shoe are made from prepared leather. They are cut using a stencil and a special punch press. In the same workshop, insoles for future shoes are cut. First, a special fabric is pressed to form an insole, then the edges are sanded, glued with rubber glue and another press is passed. The next stage is the marking process, here the seam lines are drawn. After that, the blanks are sent for firing, after which the edges are thin and pliable for further work.

The next stage is the sewing shop. With the help of special machines, prepared parts are sewn together. After their connection, thermoplastic inserts are glued to keep the shoes in their original form. After all the main processes, the workpiece is processed by a machine that prepares the real sole for gluing. The sole is prepared in a special oven, after it is glued to the boot, the excess parts are cut off. This stage is final. After that, the boot is polished with wax and the laces are threaded.

cutting shop

To obtain the details of the future boot, two punching presses are needed. One for working with the upper parts of the shoe, the other for the lower parts.

Cutting video:

Insole production

Shoe insoles are most often purchased separately. For the production of insoles, a press is needed for its formation, a machine for grinding the insoles and for spreading it with glue.

harvesting area

For this section, several machines are needed: a twinning-tape machine, which aligns the details of the top, making their thickness the same; for branding props; for lowering the edges of parts; for duplicating details of uppers, linings and hot-melt materials.

sewing area

For the sewing section you need: sewing machines; sewing conveyor; machine for inserting toes, for folding edges, for smoothing seams and for forming leather patches on the toe of a boot.

Video about the final stage:

Necessary equipment

Today, there are a large number of manufacturers of various equipment for the production of footwear of all kinds: rubber, men's, women's, orthopedic, children's, winter, summer, etc.

To work on the assembly site, you need a large list of equipment:

- assembly line;

- machine for nailing insoles;

- machine for forming stripes on the toe of the product and backs;

- tightening and moisturizing machine;

- a machine for ruffling, for marking, for removing shoes from blocks;

- machine for smoothing the shaft, for polishing and cleaning;

- walk-through dryer;

- cooling tunnel;

- thermal activator of adhesive films;

- seam press.

Video about the technological process of the ECCO trademark:

Materials for production

The best material for the production of shoes is genuine leather. Leather for domestic footwear production is offered by the Russian factory Ronnon. In addition to this factory, there are a large number of other industries dealing with natural leather in the country. Leather purchases are measured in tons. The cost of leather can be different and depends on its type:

- per m2 of cattle skin the price is 150-180 rubles;

- per m2 of suede - 50-150 rubles;

- per m2 of perforated leather price from 100 rubles.

Package

Shoes are packed in boxes that are made to order, by special factories that make packages with the name of the company or factory on it.

Business organization

Square

The required production area is approximately 7 thousand square meters. m., this is taking into account different workshops, premises for warehouses and offices. All communications must be carried out to the production premises: electricity, taking into account the load from the operation of machines, water supply and gas pipelines.

Certification

Shoes for adults are certified at the discretion of the manufacturer, while children's shoes must go through the certification process. Adult shoes must be declared. Manufactured shoes must comply with the necessary GOSTs and are controlled by SES. Certificates of conformity and a declaration are received by shoes without production damage, of the same size, etc.

Sales

If the goods are of high quality and presentable appearance, then the demand will be good, therefore, for its sale, it is possible to conclude agreements with large retail chains.

Investments

The amount of investment in the production of shoes from scratch will be approximately 180 million rubles. The payback period is about 4 years.

Shoe production: what equipment is needed + shoe manufacturing technology - 9 main stages. What you need to organize the work of shoe production: raw materials, premises, personnel + detailed financial calculations.

Capital investment (factory): from 150,000,000 rubles.

Payback period for footwear production: 3.5 - 4 years.

The Russian market is full of goods that are produced all over the world, but the situation is not so good with domestic producers.

Most likely, this is due to the fact that countries like China produce a large number of products for every taste.

Yes, it's not very high quality. However, its prices are quite low, while well-known foreign brands of high quality have a correspondingly high cost.

One such industry is footwear production. This type of activity is also not particularly developed in the Russian Federation.

Therefore, we can assume that if you create an excellent product offer on the territory of Russia, then demand will also appear.

This business is not for everyone.

You need to be a person who understands all the subtleties of the tailor profession. Also have experience in tailoring, repairing or manufacturing shoes.

Even if you yourself do not plan to work, but only to manage, such experience will help determine what may be needed for production.

What format to choose for the production of shoes?

To summarize, we can distinguish two formats for the production of shoes:

- a small place where the master sews shoes to order or for retail sale;

- full-scale production, factory.

The first option is chosen when there are no funds for the arrangement of a large enterprise with a factory building and a large staff.

In this case, you can try to open a small boutique with designer shoes.

But to reveal all the possibilities, if available, both for a novice entrepreneur and for an experienced businessman, will allow the option with a shoe factory.

The cardinal difference is that in the case of a large production, it is necessary to focus on its mass character, the speed of release of new models and accessibility for the masses.

And in the case of a private boutique, the main task is the production of exclusive models with individual design, as well as the highest quality.

Another point on which the shoe production format differs is its style. It is necessary to diametrically separate the sports and classic format.

If there are no particularly complex differences in the technology of sewing summer sandals and winter boots, then sneakers are a completely different type of product, the production of which requires different knowledge, technology and equipment.

Basic equipment for the production of shoes - what is needed?

Regardless of the size and purpose of a shoe factory, it is clear that without sewing machine can't get by.Already delving into the nuances of production, we can emphasize the fact that the standard model will not work when working with leather and other hard materials.

Detailed list |

|

|---|---|

| 1) transition bending machine and the edges of some parts - 640,000 rubles. 2) setting to create a form 3) special press 4) grinding equipment 5) installation that lowers the edges of the parts Total: from 1,850,000 rubles |

|

Optional equipment, | 1) special installation that will attach some parts with glue - 460,000 rubles. 2) equipment that will 3) installations that will fasten 4) production conveyor - 465,000 rubles. 5) a cutter for dividing the material into parts, Total: from 1,970,000 rubles |

For finishing | 1) tightening - 240,000 rubles. 2) moisturizing - 155,000 rubles. 3) drying - 550,000 rubles. 4) cooling - 445,000 rubles. 5) thermal activation of adhesive layers - 6) removal of pads - 225,000 rubles. 7) smoothing the shin area - 8) final cleaning and Total: from 2,125,000 rubles |

In most cases, you may need additional equipment, the choice of which will be determined by the characteristics of production. This is due to the desire to innovate even in such a familiar industry as the production of shoes.

Well-known brands are especially active in this.

Notable examples are Geox's "breathable shoes" and Reebok's "Easy Tone" soles (which, according to the ads, help tone the butt muscles).

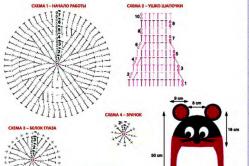

9 stages of shoe manufacturing technology

- Farther markings are applied where and how the connecting seams will pass.

- The edges of the parts are fired and polished in order to make them thinner and more suitable for further stitching.

- Seamstresses start sewing, which give the workpiece the shape of future shoes.

- Thereafter plates are attached, which give the shoe the ability to remain in its original form, without losing shape under the influence of temperatures.

- The process of tightening the laces into the finished product always done manually.

As with any sewing process, it all starts with a pattern.

If we consider an example in which we have already finished processed leather or other material of the color we need, then the next step will be the manufacture of parts.

These components are cut out with the help of special cutters according to a pre-prepared stencil of the future product.

To make one shoe, on average, you need to divide a piece of material into 20 or more parts. But it all depends on the complexity of the idea of this model.

The next step will be shoe insole shaping.

This is done with the help of special equipment - a press.

This apparatus, using a strong compression method, connects several layers of different materials, and gives a certain shape and curves to the shoe insole.

The last step in manufacturing is connection of the workpiece with the sole.

The sole itself is made in a special oven, after which it is processed and cut off all unnecessary.

After connecting with the sole, finished model being polished.

This is done with the help of sheep wool and a special wagon for shoes.

What raw materials may be needed for the production of shoes, and where is it best to take them?

Since we are still talking about the production of good and high-quality shoes, natural leather is considered to be the main material for its production.

It is not necessary to contact foreign companies for the supply of high-quality material, since half of the cost will be only delivery, and customs expenses and.

Throughout Russia, there are many enterprises that offer material for the manufacture of shoes. You can refer to such as:

- "Ronnon" - Moscow ( https://www.ronnontk.ru/leather)

- "Ostashkovsky plant" - Tver region ( www.okz.ru)

- "Russian skin" - Ryazan ( https://www.leather.ru/ru)

- "Kirov Tannery Arteks" - Kirov ( www.arteks.su)

And this is not a complete list of all Russian leather factories.

Chemical production materials will also be needed for further processing of this skin. Chemical treatment means various liquids, creams, oils etc.

For processing shoe soles, you may also need liquid polyurethanes. All this can be ordered from local chemical plants. Again, there are more than enough of them on the territory of Russia.

Packing material most often ordered from companies that manufacture custom-made packaging. Most often, the larger the order, the cheaper the unit.

How to choose the right room?

Space for small production.

If we are talking about mini-production, you can get by with a small room.

Some of the equipment that will be needed for conveyor production is not needed in this case, since half of the work will be done manually.

Also, as a rule, in the production of this format there is no need for a large number of personnel.

Based on these data, it can be determined: you need a room with a small area.

But the general requirements for production remain unchanged, regardless of its volume:

- the presence of a gas pipeline;

- plumbing installed;

- availability of telephone lines;

- the electrical wire is able to withstand the load corresponding to the features of production;

- heating and thermal insulation are also important, since the storage of material for manufacturing requires a certain temperature regime.

Nowadays, quite often there are workshop points where the store itself is located in the same building with.

This makes it possible to save on rent and sell products on the spot.

A place for a shoe factory.

In the case of a large-scale shoe-making workshop, it is obvious that it is better to choose a factory room in the industrial zone of the city.

Usually, the cost of renting or buying a building in this part of the city is not that high.

If all the necessary areas are included (office department, manufacturing, tailoring and processing workshops, staff room and warehouse), an area of \u200b\u200babout 7,000 square meters will be required. m.

How to organize work in a shoe shop?

Selection of personnel for the mini-production of shoes.

For a small trade + production point, in fact, one person is quite enough. But for greater convenience, it is better to separate the administrative work and the process of creating a product.

Ideally, you need at least one more administration representative(for example, manager or salesman, if the production is located in the same room as the store), designer(since we are talking about designer shoes), cutter and seamstress in one person, and master who will take care of all the installation and similar work.

Shoe factory staff.

For the operation of a full-fledged shoe production, in addition to a sufficient amount of equipment, it is necessary to hire a fairly large staff.

In general, about 150 people are needed to work in production (based on the fact that they will work in two shifts). And we are only talking about workers in the sewing and other workshops!

There will also be enough administrative staff, as well as warehouse workers. But, again, it all depends on the characteristics of the enterprise.

Each manager determines the exact amount himself, depending on the scale of what volume he is interested in.

Sales and sales of shoes

You can sell shoes both through and with the help of various showrooms and boutiques that sell various brands.

The second option is much more profitable - there is no need to pay for the rental of premises, wages, etc.

All that is needed is to simply provide the goods to the store for sale, set a certain amount per unit, depending on the model. The mark-up that the store sets, its owners can take for themselves.

In fact, there are many methods for selling shoes: from a point in the market to a large gallery in a shopping center. But the method indicated above is considered the most profitable.

Capital for the organization of shoe production. Profitability.

In the case of a small point of production and sale, it is difficult to calculate the costs.

We can definitely say only that this business will pay off faster than factory production. Already in the first year of work, all initial costs should pay off, after which the company will begin to make a profit.

If not, this will be a sign that you need to change the strategy.

In the case of a large workshop for the mass production of shoes, approximate figures can be given - from 150,000,000 rubles.

This amount includes the cost of not only equipment for the production of shoes, but also rent, wages, utilities.

| Item of expenses | Amount (rub.) |

|---|---|

| Total: | from 150,000,000 rubles |

| Business registration | 5 000 000 |

| Premises rent (year) | From 25,000,000 (7,000 sq. m. in the Moscow region) |

| Utilities (year) | 10 000 000 |

| Compensation (for approximately 150 employees) | From 3 000 000 / month From 36,000,000 / year |

| Equipment for the production of | From 5 945 000 |

| Raw materials (material for manufacturing) | 25 000 000 /year |

| Freight transportation | 2 000 000 /year |

| Rental of premises for the sale of shoes (about 5 pcs.) | 30 000 000 /year |

| Other expenses (troubleshooting, advertising, events) | 11,000,000 / year |

If we take into account the average indicators of domestic production, then the profitability of such a business (on a large scale) will be about 48-50%.

It can fully pay off in 3.5-4 years of work.

The development of this production is impossible without knowledge of all the nuances of the industry.

How is the shoe made? All manufacturing steps are shown in the video:

Conclusion on how to start the production of shoes and what is needed for this?

Taking into account all the above, we conclude: footwear production large scale is not so suitable for entrepreneurs who are not ready for such huge costs, and also do not have the opportunity to wait for payback for such a long time, since they do not need large scale equipment for the production of shoes.

However, it is always possible to start with a smaller business, but in this case, you can expect success only if you have really fresh and interesting ideas.

Useful article? Don't miss out on new ones!

Enter your e-mail and receive new articles by mail

An entrepreneur considering the production of shoes as a business idea must be prepared for serious investments and the need to carefully study all the nuances of the industry. In addition, the segment is highly competitive. And if it is quite easy to compete with domestic factories, then to ensure the same high quality as that of European manufacturers, you will have to try. On the other hand, Chinese suppliers, who are not really striving for high performance characteristics of goods, offer the lowest possible prices, can become a serious problem.

Features of this business

Footwear production is a costly and complex type of business in terms of organization. In addition, the entrepreneur must understand the technologies and types of products. Otherwise, it is impossible to create a product that can compete with a huge number of domestic and foreign brands. However, new manufacturers are constantly entering the market. So, if you have original ideas and a carefully thought-out strategy, there is every chance of success.

To do this, you need to decide what kind of shoes to produce. Traditionally, it is divided into women's, men's and children's for everyday wear. Here the competition is the highest, and the leading positions are occupied by Chinese suppliers of inexpensive goods. That is why many novice shoe manufacturers from Russia immediately go into narrower segments - the manufacture of shoes for the military, athletes, dancers, representatives of various professions, orthopedic, etc.

There are a number of factors to consider when choosing a niche. For example, women's fashion and sports shoes have a high cost, and also require the organization of high-tech and expensive production. In the case of the manufacture of rubber boots and beach slippers, the starting costs will be much lower. On the other hand, any investment can be justified if the target audience is correctly defined, the design is developed and brand promotion activities are competently carried out. By the way, entrepreneurs who managed to create an original solution and promote it on the principle of viral content are often the most successful.

Another component of success is the ability to follow fashion trends. Even excellent quality shoes will not be sold in volumes that a new product from a well-known brand can claim. At the same time, do not forget about branding - products should be easily recognizable among the "neighbors" on the shelves.

Raw material

Quality shoes can only be obtained from quality raw materials. Accordingly, you will need to find bona fide suppliers and sign a cooperation agreement. What raw materials are required depends on the type of footwear produced. Good leather is essential for leather models. Manufacturers of this material can be searched both in Russia and abroad. The choice is largely determined by the planned production volumes. The minimum order from large suppliers, as a rule, is at least one ton of leather. But you can establish contacts with small factories and buy 300-500 kg. You can familiarize yourself with the list of leather industries in the Russian Federation, their prices and specifics.

You will also need accessories, dyes, liquid polyurethanes, reagents, creams, oils and other consumables.

Don't forget about packaging. Shoes are sold in boxes wrapped in paper. You can order such containers at the nearest factory of the corresponding specialization. At the same time, the main thing is to think over the design of the boxes - different for different models.

Manufacture of leather shoes

Equipment for the production of

Today, in the profile market, there are many manufacturers of the most diverse shoe of all varieties, and its list is quite impressive. In addition to the industrial conveyor, mechanisms and devices are used that perform certain operations.

For cutting, special machines are used. Hydraulic cutting presses are used, as well as automatic cutting systems. These machines need special cutters (stamps), the manufacture of which is individually for a specific shoe model. But this is justified only for industries with a large turnover. For small batches, it is more expedient to use manual legs complete with tables, cutting plates, punches, etc.

The main cutting equipment includes:

- splitting machines and machines;

- punching press;

- machines for turning leather, lowering edges and rolling backs;

- embossing press;

- guillotine for small parts of the skin.

The subsequent stages of production will require equipment of various functional purposes. These are machines for the formation of various components of finished shoes - soles, insoles, heels. Apply:

- skin peeling machines;

- machines that produce the edges of the skin;

- presses duplicating additional lining material to increase wear time and improve the quality of shoes;

- gluing machines facilitate the work of gluing ribbons and soles;

- a machine that bends the edges of the material and cuts off the excess;

- equipment for working with different types of braid;

- equipment for the volumetric formation of a stripe on the toe (socks);

- presses that produce embossing and die-cutting of the upper layer of material for making decorative elements, drawings, ornaments;

- machines for fastening shoe accessories.

The sewing process takes place using industrial shoe sewing machines, which must perform various functions. A full work cycle will require five sewing machines:

- Flat - for the assembly of non-voluminous blanks;

- Core - for the assembly of bulk workpieces;

- For flashing the lining - a zigzag machine;

- Heavy machine class - for sewing decorative seams, edges;

- Repair.

Shoe equipment is divided according to its main purpose:

- moisturizing the heel to give it the necessary elasticity;

- pasting the back into the workpiece and tightening - the formation of the entire heel part;

- tightening the sock on the block;

- lining processing;

- leg tightening;

- steam finishing and firing of threads with a hairdryer;

- sock moisturizing;

- smoothing defects with steam;

- cooling with a refrigerator;

- spraying glue;

- gluing the back seam;

- near the top layer of material;

- fixing the insole to the block;

- sole pressing;

- heel attachment.

The following equipment is required for the final production processes:

- Polishing machine with a rotating shaft and brushes (finisher);

- Device for the formation of the shaft;

- Chamber for painting and applying waterproof components;

- Sole gluing equipment.

Production technology

The process of making shoes from leather, suede and their substitutes is quite complicated. It includes a number of operations:

- Cutting. At this stage, details are cut out of the material. It may take about 30 or more pieces to make one shoe or boot.

- Insole manufacturing. In some cases, it is more profitable to work with ready-made insoles from a third-party manufacturer. If you decide to establish your own production, you will need to buy a number of units.

- Marking blanks. Marks are applied to the cut parts, along which seams will be made at the next stage. Next, the edges are fired, painted and polished.

- Sewing. The parts are sewn together in a certain sequence, then thermoplastic inserts are placed in the blanks, for which the pairs are laced up and placed on a metal foot heated to 150 ° C, which is then quickly cooled to -20 ° C.

- Product assembly. The blanks are placed on a ruffler, where they are straightened and cleaned of possible contaminants. Semi-finished products are sent to a special oven with a temperature of 60 ° C, and then the excess is cut off at the edges. After the sole is glued or sewn to the top of the product.

- Polishing and lacing. At the final stage, the shoes are polished with sheep's wool smeared with wax and laced by hand.

The footwear production technology is quite complex and requires an extensive fleet of equipment. In general, it is not possible to determine its cost and composition, since everything depends on the type and volume of manufactured products. You can get a general idea of \u200b\u200bprices and assortment on thematic sites, for example, on Tiu.ru. The lines of European manufacturers such as Durkopp Adler, FAV, Gilardi, Camoga enjoy a good reputation.

How handmade shoes are made by masters of their craft:

Production of felt shoes

On an industrial scale, felt boots and other felt products are made from semi-coarse sheep wool, which is purchased from sheep farms. On the territory of the Russian Federation, most of them are concentrated in the Volgograd region. You can also buy wool in Kazakhstan, Uzbekistan, etc.

After delivery to production, raw materials are checked for quality, sorted and placed in trunks. At the first stage, the wool undergoes a special treatment, after which it is aged for 24 hours and transferred to long-needle carding machines. The resulting fibers are loosened on scutching and carding machines. Next, the semi-finished product undergoes chemical treatment and is sent for compaction, as a result of which a thick and soft fabric is obtained, from which various felt products are subsequently obtained.

Felt boots themselves can be made both manually and industrially. The canvas is once again tested for quality and placed in a sculpting machine, where, under the influence of heated water and mechanical factors, the final rolling is performed. Sulfuric acid can be used to reduce the cycle time, but due to its danger to the health of personnel, this method is rarely used.

After the felt boots are rolled again, doused with steam and dried at a temperature of about 100 ° C, cut off and fed for cleaning. Ready felt shoes are put into pairs, insoles are put in, packed and sent to the warehouse. If necessary, at the same stage, the products are decorated with embroidery, appliqués or in another way. There are also models with a rubberized sole, which is “applied” by the vulcanization method.

To open a small workshop for making felt boots, you will need to buy a carding machine (about 150 thousand rubles), a steam press (about 30 thousand rubles), a washing machine (90-100 thousand rubles), weighing equipment (10-12 thousand . rub.). 2-3 people are enough to service the workshop.

Large-scale production will require more substantial investments. A set of equipment with a capacity of 50-70 pairs of felt boots per shift will cost 800 thousand - 1 million rubles. An embroidery machine and a sole vulcanizer may also be required.

The above equipment makes it possible to produce felt boots of different colors and models. Additional income can be obtained by producing decorative items made of felt, shoes for fishing, tourism, boots with soles and other goods. For example, it can be car or door mats, slippers, bags, insoles, vests, treatment belts.

Production of rubber shoes

This industry has prospects in the Russian Federation, since many regions are characterized by heavy rains. Also, such products are an integral part of the uniform of representatives of many professions. As an example of a successful business, one can cite such domestic manufacturers as Pskov-Polymer, PK KhimProm, Dailos LLC, Tomsk Rubber Footwear Plant LLC, PKF Duna-Ast LLC and Sardoniks LLC.

Work on the creation of rubber boots begins with the development of models, which will require the involvement of a technologist and a designer. Modern shoes should be durable, comfortable and beautiful. There are three ways to make rubber shoes - assembly (by gluing), stamping and molding. They differ in the number of parts and how they are connected. Glued shoes like galoshes contain the largest number of elements (13-21 parts). Two other methods make it possible to reduce the number of elements by 3-4 times.

The process begins with the receipt of sheet rubber. To do this, a mixture of rubber, filler, vulcanizing agents, reaction catalyst, pigments and regenerate is placed on calenders, where sheet rubber is formed for the manufacture of shoe upper parts. The sole is cut out of a special profiled rubber sheet. Also on the calenders, textile materials are smeared and covered with a rubber mixture. However, to increase the profitability of production, it makes sense to use PVC instead of rubber. This material is 25-30% cheaper than a rubber base, and in terms of consumer properties it is in no way inferior to it.

The materials used for the manufacture of internal and intermediate parts are rag mixtures with the addition of unvulcanized scraps of rubberized textiles. For the manufacture of lining, backs, insoles, socks, decor, various cotton fabrics are used.

With regard to the production of rubber boots, boots and shoes, the most common method is the molding method, when the creation of the carcass and the vulcanization of the products are carried out at the same time. At the first stage, the details are cut out. Then a kind of “stocking” is created from textiles, which is put on a metal block and “wrapped” with rubber elements. The blank is placed in the mold of the vulcanizing press, where the rubber is converted into rubber. Then the shoes are sent for trimming and pressing out, undergo quality control, are packed and sent to the warehouse.

Forming method:

The average cost of a production line is about 2.5 million rubles. It is not worth saving, because the characteristics of the equipment determine the quality of the final product.

Manufacture of sports and special footwear

The production of sports shoes differs significantly from the manufacture of its other types, primarily by the use of complex modern technologies, the high cost of equipment, raw materials and accessories.

It uses technologies designed to make shoes as comfortable, lightweight and stylish as possible, as well as to provide them with accessibility. The main difficulty is that existing manufacturers are in no hurry to disclose information about their own developments, so a new market player will have to invest a significant part of the funds in finding their own solutions. And it's expensive.

An example is the recent 3-D printing technology, which creates sneakers that perfectly follow the line of the foot. To date, the mass production of "printed" sneakers is only being introduced by Adidas, but there are prerequisites for the fact that in a few years the solution will be released to the masses.

Another example of innovative implementations is Nike's Flyknit technology. Shoes are made by continuous weaving, without lining and textile inlays. This allows you to minimize the number of seams that can cause discomfort during intense sports.

Significant financial resources are required to create the solutions mentioned above. At the initial stage of activity, it makes sense for a sneaker manufacturer to work with traditional materials, as well as to select several patterns that meet the needs of the selected target audience.

Classic sneakers contain three structural elements - the upper, the midsole and the main sole.

For sewing the top, natural and eco-leather can be used, as well as mesh materials made of nylon and polyester threads, a characteristic feature of which is light weight and excellent breathability. The difference between leather sneakers made of natural and synthetic materials is the ability of the first to deform during operation. The latter are more durable and hold their shape better, but have a lower air permeability. There are also a number of special fabrics for the uppers of the sneakers, designed for specific needs.

The midsole is necessary to provide comfort during active loads, cushioning and support of the foot. That is why it depends on the characteristics of this element how much this or that model of sports shoes will be in demand. The most commonly used materials for midsoles are:

- Philo. This is a lightweight foam compound made from EVA granules with excellent cushioning properties and the ability to take any shape.

- Polyurethane. Some time ago, due to its strength and hardness, the material was in demand in the production of sneakers. However, now, with the advent of new solutions, it is used less and less - primarily because of the large weight.

- Philite. The composition is obtained by adding rubber to phylon. This makes the shoes somewhat heavier, but in return increases its elasticity.

- EVA. Lightweight, flexible and inexpensive material that is often used for budget running shoes. Over time, under the wearer's weight, air is forced out of the foam, and the sole ceases to perform its functions.

In professional models of sneakers, more complex materials are used, such as Lumarlon, Nike Epic React and others.

For the manufacture of the main sole, the main function of which is to provide high-quality grip on the surface, there are also many options. The most budgetary of them is Duralon. It is made from blow molded synthetic rubber. Products cannot boast of durability, but they have excellent shock-absorbing ability.

Another rubber compound is BRS 1000. For its manufacture, carbon is introduced into synthetic rubber. The result is a durable material ideal for running shoe bases. The DRC rubber compound soles offer superior durability and excellent performance in almost any kind of activity required in sports such as tennis and track and field.

In the case when it is not possible to experiment with different materials within the range, you can use a universal material - pure rubber. It is obtained by mixing several types of rubbers of artificial and natural origin. Due to its reliability and good grip with the surface and low cost, this solution can be used in almost any type of sneaker.

As you can see, the manufacture of special footwear is one of the most complex and costly segments of the industry. However, this is where you can count on the maximum profit.

Company registration

The scale of footwear production depends on the desire and capabilities of the entrepreneur. It can be a small atelier, a medium-sized enterprise or a large factory with an assortment of several hundred items. Accordingly, different documents will be required. For an atelier, status is sufficient, in other cases it is necessary. This will allow you to work with large batches of products. A lawyer will help you decide on the choice of taxation system.

When registering, you will need to indicate the OKVED-2 code 15.20 "Shoe production". This will make it possible to produce all types of shoes and parts for them, except for orthopedic, asbestos, rollers and skates for figure skating.

Close attention must be paid to the registration of the company name and logo. The name should be easy to remember and preferably not too long. When choosing a name, you need to take into account the presence of restrictions. First, you need to make sure that another entrepreneur has not already registered a similar name. Secondly, when using the names of cities, countries and some other subjects of the Russian Federation, the law prescribes obtaining permits, which will entail costs. The name must be registered in Russian, and if desired, in English and other languages. If the entrepreneur does not have experience in preparing such documents, it is advisable to contact a specialized company.

All types of footwear are subject to sanitary and epidemiological control. A manufacturer of children's shoes will have to obtain a mandatory quality certificate. In the case of products for adults, certification is voluntary, but a declaration is still required. In addition, products must comply with state standards.

Product certification

The certification procedure for footwear in the countries of the Customs Union (CU) is required not only in production, but also in trade. For adult men's and women's shoes, certification is optional. Obtaining documents of conformity is mandatory only for children. Be sure to have the necessary documents certifying that the product of production or sale is of impeccable quality.

For an adult, this can be GOST or technical specifications (TU). Today GOST 26167-2005 is in force, for children - GOST 26165-2003.

Certification involves checking shoes for quality, product characteristics by name, gender and age, types, materials used, raw materials and components for the bottom and top of shoes, seasonality, methods of attaching parts, finishing. It also includes a characteristic and the presence of an insulating lining.

People have been thinking about protecting their feet from cold and damage for a very long time. Today's shoes, already familiar to us, have gone through several thousand years from the simplest, sewn pieces of leather, woven sandals and carved wooden shoes to products consisting of many parts and requiring entire factories to manufacture.

In some ways, modern shoes and their distant ancestors have much in common, only today there are increased requirements for today's items: any buyer wants shoes not only to protect the feet from damage and be comfortable, but also meet the latest fashion trends and please the eye.

Market

To date, experts note the high dependence of the Russian market on foreign manufacturers and imports. At the same time, the constant increase in prices for shoes from abroad attracts the attention of the consumer to the domestic manufacturer. For an entrepreneur planning to open his own shoe factory, this is obviously a big plus. Along with these processes, marketers see the growth of the market and promise to reach the pre-crisis level of 2008 by 2013.

Technological process

Like every shoe that comes off the assembly line, the manufacturing process has many parts. At the first stage, in the cutting shop, the components of the future boot are made from the obtained, already dressed leather. Usually, the number of such parts is about 30 pieces for one product. They are cut out using stencils (or cutters) and a special punching press installed in the workshop. This machine operates in several modes set by the operator. The setting of the mode depends on the thickness of the material and the height of the cutter, depending on the mode, the height from which the press is lowered changes.

In the same workshop, insoles for future boots are also cut out, but with the help of another press specially designed for such work. First, a special fabric is pressed on both sides, forming an insole, then the edges are sanded. Then, the blanks are glued with rubber glue. Future warm insoles pass through another special press.

The next workshop is filled with markers who draw lines for future seams with a pencil. After marking, the workpieces are sent to firing, where the edges of the parts are heat treated, painted, and then polished using a special machine for lowering the edges, as a result of which the edges become thin and suitable for stitching.

The next workshop is a sewing workshop. Here, with the help of special machines, seamstresses sew leather parts to obtain blanks. After connecting the parts, thermoplastic inserts are glued into the blanks, thanks to which the shape of the boot remains in its original form for a longer time. These inserts are put on a metal foot heated to 150 degrees Celsius, after which the workpiece is immediately cooled at a temperature of -20 degrees. Deformation of the workpiece at this stage is also prevented by temporary laces threaded into the workpiece.

After all the main operations for stitching the workpiece, the resulting semi-finished product is sent for processing to the so-called "ruffle robot". This machine prepares the temporary sole for gluing a real rubber sole by leveling and removing dust from the surface.

At the next stage, the sole is glued to the workpiece, previously “baked” in a special oven at a temperature of 60 degrees. After that, unnecessary rubber residues are cut off from the sole. After that, the boot can be considered ready. It is polished with sheep's wool smeared with wax.

The final step in creating a boot is threading the laces. This process is done manually.

Equipment

The complexity of the technological process of sewing shoes necessitates a large number of specialized equipment.

Today, there are a sufficient number of different manufacturers of equipment for the production of shoes of various types on the market. We will not focus on manufacturers, paying attention to the role of each machine in production.

cutting shop

In the cutting shop, two punching presses are necessary to obtain the necessary parts for the future boot. One of them does the work related to the details for the upper part of the shoe, the other for the bottom and multi-layer flooring.

Insole production

Shoe insoles are produced either in a separate workshop, or, quite often, they are generally purchased separately. If you plan to make insoles yourself in your production, you will need the following equipment:

- Insole press

- Chamfering Machine: This machine sands the edges of the insoles

- Half insole glue machine

- Hydraulic press to form a warm insole (optional)

- Shoe hemming machine

harvesting area

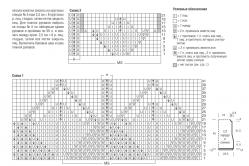

There are four vehicles in this area:

- Twinning and tape machine: this machine aligns the details of the upper, making the thickness of the upper uniform.

- Props branding machine: with it, each pair of shoes receives its own identification number.

- The hemming machine makes the upper part of the shoe easier to sew by thinning the edges of the parts.

- Machine for duplicating uppers, linings and hot-melt materials.

sewing area

As the name implies, in this section, the prepared parts are connected into a workpiece. For this process you need:

- sewing conveyor

- Special sewing machines

- Installation for spreading glue (in case some parts will stick together)

- Subsock Inserting Machine

- Edge bending machine

- Back Seam Smoothing Machine

- vamp molding machine

assembly area

Assembly line

- Insole nailing machine

- Vamp shaping and shaping machine

- Back shaping machine

- Tightening machine

- Humidification Machine

- Pass dryer

- Cooling tunnel

- blowing machine

- Ruffle machine

- Marking Machine

- Thermal activator for adhesive films

- Seam press

- shoe removal machine

- Shaft smoothing machine

- Polishing and cleaning machine

Various machines and machine models are available from manufacturers: Atom, Banf, Camoga, Cerim, Comelz, Durcopp Adler, Ecom, Elettrotecnica, Iron Fox, Knaoz, Matic ? Verdi, Mav, Mec-Val, Neve, Obe, Officina Meccanica, Pfaff, Rachioni, Selmac, Sicomec, Silpar, Volonte and others. All of them have representative offices in Russia.

However, delivery of the equipment, as a rule, is made strictly under the order. Related to this is the unavailability of the pricing policy of equipment manufacturers in wide sources of information. Therefore, the price of a particular machine will have to be found out from suppliers during the order or as a consultation.

Raw material

The main material for the manufacture of high-quality shoes is leather. Natural leather for shoe production is offered by the Moscow factory "Ronnon". In addition, there are many leather industries throughout the country. Among them: the Ostashkovsky tannery (Tver region), the Russian Leather factory (Ryazan), the Smilovichi tannery and others. As a rule, purchases are calculated in tons. At the same time, the most common minimum order is 1 ton, but there are factories ready for minimum orders from 300 kilograms. Depending on the type, the cost of leather varies:

- from 100-180 rubles per square meter (bovine skin)

- from 50 - 150 rubles per square meter (suede)

- from 100 rubles per square meter (perforated leather)

Chemical materials for the production of shoes are provided by the company Titrus. Among chemical materials: finishing materials: finishes, liquids, creams, oils, edge and seam preparations, adhesives, reagents for preparing the surface for gluing, liquid polyurethanes for the production of soles, paints. Prices must be checked with suppliers.

Package

Shoe boxes are produced in special factories dealing with various packaging, ready to make packaging especially for you with brand or factory name. Among such manufacturers in our country are Planet Upakovka, Antek, Iris Pack and others.

Organization of production

The factory must have sufficient space for the installation of equipment and convenient work for operators. The required area of the factory, taking into account workshops, warehouses and office departments, can be up to 7 thousand square meters. As for operators, not all machines have automatic mode, therefore, machine workers will be required for almost every machine. For constant, uninterrupted production, you will need as many operators as will be enough to operate production in two shifts. On average, about 250 people will be required to work in production.

All necessary communications must be connected to the factory: electricity, gas and water supply, telephone installation. It is necessary to take into account the loads, in particular the electrical load, which, due to the operation of the machines, can be up to 50 kW.

Certification

Certification of footwear for adults is a voluntary process, for children it is mandatory. Manufactured shoes for adults are subject to mandatory declaration. Shoes intended for wearing, except for sports, national and orthopedic, must comply with a number of GOSTs. It is possible to receive a certificate of conformity and a declaration only for shoes without production damage, the same size in pairs, with correctly connected parts, etc. All footwear in the Russian Federation is subject to sanitary and epidemiological control.

Sales

As in many other cases of the production of consumer goods, the best option for the sale of shoes would be to conclude contracts with large Russian chains such as Ecolas, Tervolin, Aty-baty and others. There are a lot of such networks now, the main thing is that you have a product worthy of the consumer's attention.

Investments

According to experts' calculations, the investments required to create a shoe factory from scratch are about 180 million rubles. At the same time, taking into account the internal rate of return of 48%, the payback period will be up to 4 years.

Ilkevich Daria

- portal of business plans and guidelines

The Russian company Ralf Ringer is already 17 years old. It has three own factories (in Moscow, Vladimir and Zaraysk), the largest distribution network in Russia (over 1,700 stores) and the largest production of men's shoes in the country. In total, in 2012, she sold about 1.35 million pairs.

Shoe company Ralf Ringer

Location

Moscow city

opening date

1996

employees

3000 people

Annual turnover

2 billion rubles

Before the start of production, future shoes go a long way. A team of brand managers, based on global fashion trends, market analysis and sales results of the previous collection, creates a technical task. On its basis, fashion designers come up with a collection, which is shown to the assortment department and company executives at the draft board. Next, models are selected that, in the general opinion, will be in demand on the market. For these models, a technological map and patterns are created, according to which the first samples are created in the experimental workshop. The already sewn collection is again shown to the expert council, which examines each style and model in stages, sends them for revision to fashion designers and approves the final assortment. Only now the collection is presented to buyers from various stores. Those models that they choose go into mass production.

The factory uses leather from four countries: from Russia - for rough men's boots, from Italy - for model classics, from Argentina - for semi-sports shoes, and from France comes the raw materials of high selection, which are used in the production of the most expensive models.

The pads take into account the structural features of the Russian foot. We have it wider and fuller than Europeans, so classic Italian shoes are often not suitable for our men. The width of the Russian foot can be not only a genetic feature, but also a consequence of orthopedic flat feet earned in childhood from uncomfortable shoes.

In this workshop, details of future boots are cut out. It is specially located on the first floor, because the presses for punching out parts are very heavy - they simply would not withstand the floors.

This is how the insoles are cut. Each shoe (with rare exceptions, moccasins, for example - without the main insole), in order to maintain dimensional stability, necessarily contains an insole made of shoe cellulose - a very dense, thick material. She, like the bones in the human body, creates the frame of the shoe.

On the table are patterns tied with twine for a boot of a certain style and size. Each such part is inserted into the cutter, which, under pressure, cuts out the corresponding parts from the material.

This is a preparatory workshop where previously cut parts are processed. They are painted over, set on fire with a special blowtorch, bent, marked with a silver pencil. Then comes the labeling of the details: on each shoe there is data on the type of shoe, color, size and lot number.

An important nuance when creating a boot is that it should not have pronounced scars, seams that can injure the leg. In order for the shoes not to rub, the edges of some parts are grinded. To control the thickness of the skin, use a thickness gauge (pictured).

In the workshop where laser perforation is carried out, there is always a strong smell of burnt leather. According to the pattern set by the program, the laser burns neat "holes" in the skin.

An automatic belt passes through the workshop, along which boxes with products travel. In order for the specialist to complete his operation, the master puts the box on the tape, presses the number of the corresponding specialist on the remote control, and the box is sent to him. When the operation is completed, the specialist returns the box with the product to the master, who sends it to the next operator.

In this workshop, the main insoles are made, which are then attached to the upper blank, and then to the sole. The details of the insoles (main and heel) cut out on the ground floor are glued together.

This machine makes a recess in the insole, into which the arch support is then inserted.

The next steps are related to shaping the boot. To do this, first, an insole made of shoe pulp is nailed to the block with three studs. Then, in special machines, the toe and heel-gel part of the boot is tightened and glued on the block. The white threads on the bobbin in the photo are polyurethane glue that is heated inside the machine.

The boot passes through a special sauna, where it undergoes a moisture-heat treatment, as a result of which it finally takes the form of a shoe. Then the workpiece goes to prepare the attachment to the sole: the drawing is washed off, the boot is pre-primed and polished, and the excess long edge is polished with a coarse abrasive.

Then the block is taken out of the boot, the insoles are inserted into it, treated with cream, tinted with water-repellent paints, additionally polished, steamed with a special mini-iron that straightens the inner toe. Shoes are also treated with carnauba wax, which is considered the most expensive material in shoe cosmetics. It is thanks to him that the shoes in stores look so sparkling.

For the correct formation of the top of the boot on the block, special production laces are used, which are replaced with ordinary ones at the end.

Then the finished boot is checked for compliance with the sample. If all is well, a paper ball is put into it, wrapped and placed in boxes. The future collection is always presented in the showroom (pictured below) at the factory, as a sample.

More than 40 people work on each of our shoes. As a rule, it contains from 40 to 60 parts, each operation is done by a separate worker. In total, the factory produces about 3,000 pairs of shoes per day.